1. Principle: non-heating, dry atomization at room temperature to avoid corrosion damage caused by condensation, no loss of sterilant, and no temperature and humidity requirements, normal temperature and humidity can sterilize work

2. No material corrosion effect, need to provide material compatibility test report, stainless steel, galvanized material corrosion

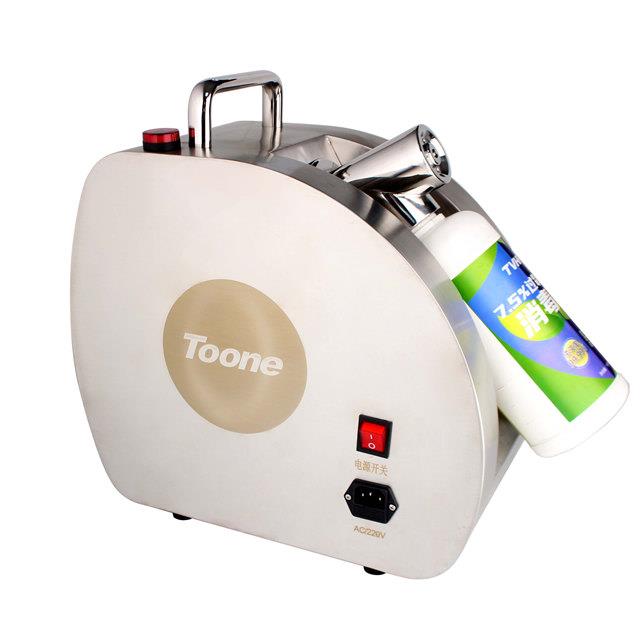

3. The main material of the equipment is L304, the surface is smooth and flflat, easy to clean, wear-resistant, and resistant to disinfection by disinfectant

4. Record the main parameters of sterilization, and support export and printout; the data in the touch screen is the original data, which cannot be deleted or changed, and can only be exported, not imported

5. The device has a 1-minute delay start, or a remote control start and stop function to ensure safe use

6. The sterilization time is 1-3 hours to complete

|

Size: 200×370×340mm

|

Weight: 9.5kg

|

|

Chassis material: 304L stainless steel body

|

Power supply: 220±12V/50Hz

|

|

Power: 220W

|

Liquid storage tank: external (optional 250ml,500ml, 1000ml solution bottle)

|

|

Applicable disinfectant: 7.5% hydrogen peroxide/peracetic acid/sporicide

|

|

|

Maximum sterilization volume: 200m3

|

Sterilization level/effect: reach Log6 kill rate

|

|

Sterilant consumption per cubic meter: 5ml/m3 |

Spray flflow rate: 21M/S

|

|

Spray volume: 12ml/min

|

Particle size: <2μm

|

|

Unique turbine speed: 28000r/min

|

Hydrogen peroxide output method: turbo-charged atomization

|

|

Data management

|

Data transmission

|

|

Touch screen size: 4.3 inches

|

Microcomputer intelligent system

|

|

Control system PLC

|

Remote control

|

|

Appointment function

|

Small size design and portable handle, convenient for personnel to carry and transfer

|

|

Mobile power

|

Mobile cart

|

|

Hydrogen Peroxide Concentration Sensor

|

Hydrogen peroxide decomposition device

|